When one considers the intricate world of luxury timepieces, Rolex stands as a paragon of precision and prestige. The question of “how Rolex watches are made” opens a narrative that weaves together the threads of meticulous craftsmanship, pioneering innovation, and an unwavering commitment to excellence. Each Rolex watch is not merely assembled; it is born from a philosophy that marries tradition with technology, ensuring that every second it measures is a testament to timeless luxury. This exploration delves into the heart of Rolex’s manufacturing magic, a journey that transcends the mere creation of a watch, embodying a legacy that ticks perfectly with both the past and the future.

The Rolex Material Mastery

Rolex’s commitment to excellence is deeply rooted in the materials they choose. The company insists on only the finest raw materials, meticulously selected for their inherent quality and aesthetic appeal.

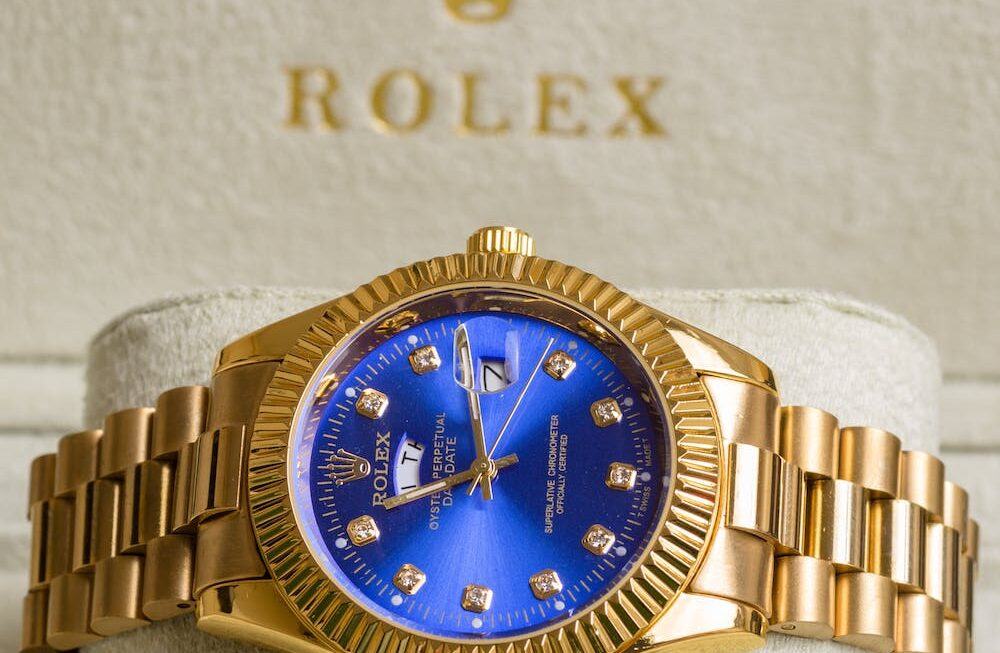

Rolex is particularly known for its use of 904L stainless steel. This corrosion-resistant alloy offers an exceptional sheen and is notoriously difficult to work with, requiring specialized machinery and expertise. In their quest for perfection, Rolex also creates their own gold in an exclusive foundry, ensuring each ounce meets their stringent standards for purity and color.

Even the sapphires and diamonds are carefully chosen and hand-set to ensure they meet the brand’s exacting requirements for clarity and sparkle. This unwavering attention to material quality sets the stage for the creation of every Rolex watch, each a masterpiece of durability and design.

Manufacturing Excellence: The Rolex Way

At the heart of Rolex’s manufacturing prowess lies a seamless blend of human touch and technological innovation. The brand’s production facilities, spread across Switzerland, are a testament to its pursuit of manufacturing excellence.

Here, in these bastions of precision, every component of a Rolex watch is crafted. From the forging of the case to the meticulous polishing of the links on the bracelet, the process is an orchestration of exactitude.

Rolex employs a fleet of cutting-edge machines for tasks that demand superhuman precision, such as the cutting of watch gears. Yet, alongside these marvels of modern technology, the steady hands of skilled artisans are ever-present, ensuring that each piece meets the highest standards.

The marriage of advanced robotics with traditional handcrafting techniques is emblematic of Rolex’s philosophy: to create watches that are at the forefront of watchmaking technology yet retain the soul of artisanal craftsmanship.

Precision and Expertise: The Rolex Craft

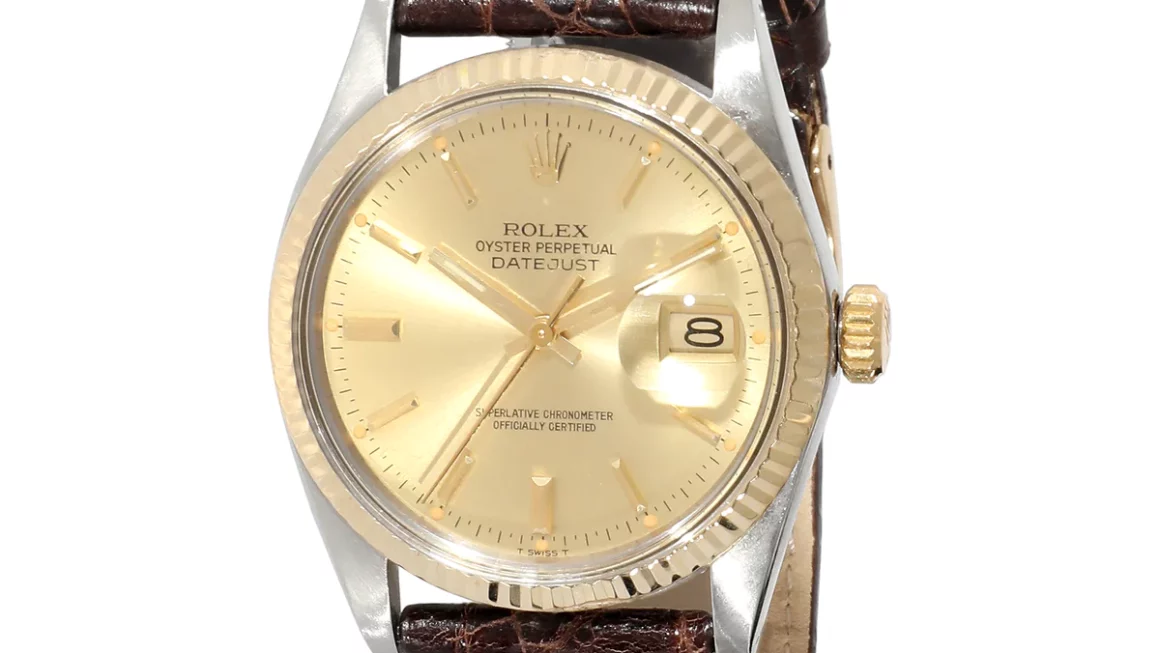

In the realm of Rolex, precision is not just a concept—it is the cornerstone of every action, every component, and every watch. The assembly of a Rolex watch is a symphony of exact movements, performed by master watchmakers with years of training and an eye for detail that rivals the instruments they use.

These experts bring together hundreds of small parts with expertise, ensuring that the heart of the watch—the movement—is assembled with flawless precision.

The expertise extends to the meticulous hand-finishing of each watch. It is here that the human element shines, as artisans polish, buff, and refine, transforming the raw materials into the iconic timepieces known around the world.

Every surface, no matter how hidden, is finished to perfection. This dedication to detail is what gives Rolex watches their unique presence and character, a luster that is immediately recognizable and deeply associated with the brand.

With the watch now assembled and polished to perfection, we will next explore Rolex’s commitment to sustainability in sourcing and manufacturing

Sustainability in Sourcing and Manufacturing: Rolex’s Eco-Friendly Commitment

Rolex’s approach to creating timeless pieces extends beyond aesthetics and precision; it encompasses a profound responsibility toward the environment. The brand’s commitment to sustainability is evident in every stage of the watchmaking process. From sourcing the purest metals to the final assembly of the watches, Rolex adheres to environmentally responsible practices.

In their own foundries where they cast gold and platinum, strict standards ensure not only the quality of the materials but also that their procurement and processing are environmentally sound. Rolex’s dedication to sustainability is also reflected in their use of solar energy and their commitment to reducing manufacturing waste. Even the sapphire crystals and diamonds are sourced with a conscientious approach, ensuring that their beauty does not come at the cost of the environment.

Rolex’s sustainable manufacturing practices are a testament to their recognition that luxury and environmental stewardship can, and indeed should, go hand in hand. This philosophy not only enhances the intrinsic value of a Rolex watch but also aligns with the values of a growing cohort of eco-conscious consumers.

Next, we’ll examine the rigorous quality control and testing that every Rolex watch undergoes to ensure it not only looks exceptional but performs impeccably.

Quality Control and Testing: Ensuring the Rolex Standard

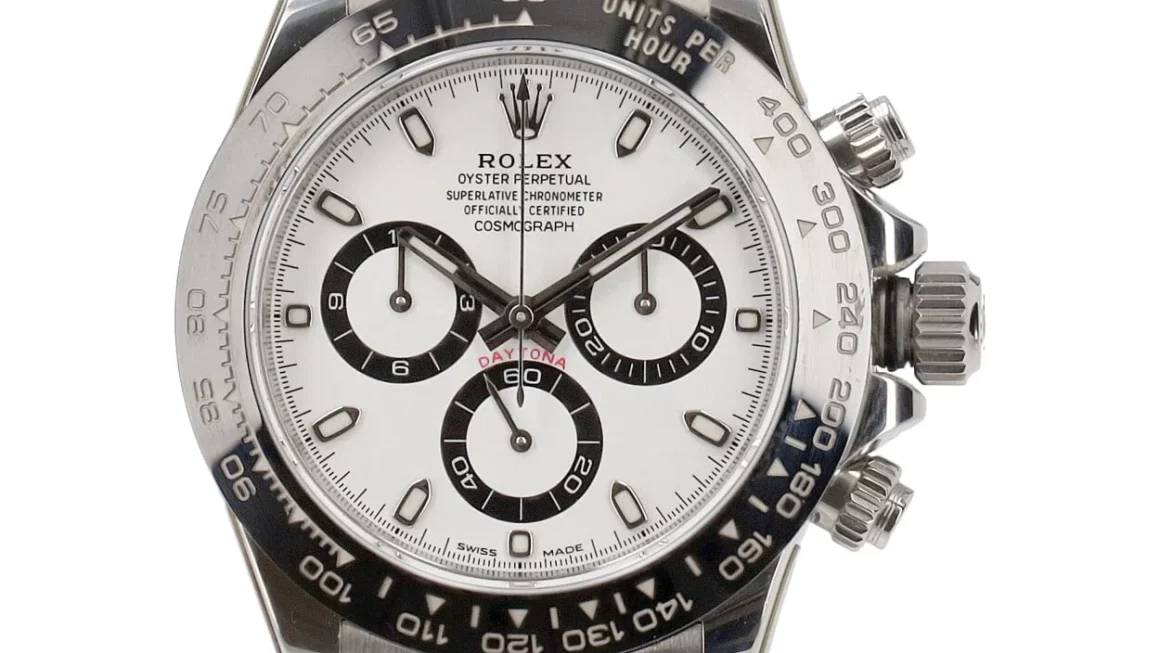

Rolex’s reputation for reliability is not a matter of chance but the result of rigorous testing and quality control protocols. Each watch is subjected to a series of examinations and performance trials that are as uncompromising as they are technologically advanced. Before a Rolex ever leaves the factory, it must pass a gauntlet of tests designed to push its capabilities to the limit.

The Oyster case, a Rolex invention from 1926, is tested to ensure its waterproofness. Each case is submerged in water and subjected to pressures that exceed those found at the depth to which the watch is guaranteed.

Similarly, every movement is tested for accuracy far beyond the standards of the official Swiss chronometer testing institute (COSC). The final check, the Rolex Superlative Chronometer certification, ensures a daily precision of -2/+2 seconds per day—more stringent than industry norms.

Also, beyond timekeeping, the watches undergo tests for power reserve, self-winding capacity, and the functionality of all their components. It is this exhaustive approach to quality that allows Rolex to stand behind every watch with a five-year guarantee, a promise of performance that is as solid as the watches themselves.

The Pinnacle of Horological Artistry

The journey through the creation of a Rolex watch reveals a narrative that is as much about innovation and precision as it is about heritage and sustainability. “How Rolex watches are made” is a story told in the language of meticulous craftsmanship, advanced technology, and an unwavering commitment to the environment. Each Rolex is a microcosm of history, an artifact that represents the zenith of watchmaking.

Moreover, Rolex has mastered the art of blending the traditional with the futuristic, the natural with the engineered, and the aesthetic with the functional. This mastery is what makes a Rolex much more than a timepiece—it’s a legacy worn on the wrist, a testament to human achievement, and a companion for life’s adventures.

As we conclude, we reflect on the fact that owning a Rolex is not just about telling time; it’s about being part of a tradition that values precision, durability, and responsibility. It’s about acknowledging that the true measure of time is not in seconds, minutes, or hours, but in the lasting impact we have on the world and the legacy we leave behind.

Curious about the craftsmanship behind every Rolex? Comment with your insights and share this post with fellow enthusiasts to spread the wonder of Rolex watchmaking.

Mark.